Lynx Kitchen 250

Lynx Kitchen 250 is CE-marked and adapted for retrofitting on all known kitchen hoods for restaurant kitchens and industrial food production

Specs

Capacity of 800m3

Duct diameter 150mm-350mm

Efficiency from 80-90%

Height of 600mm

Power consumption 90W

Norwegian product

Our product is proudly Norwegian-made, characterized by high quality and sustainability. With a focus on precision and care, we deliver outstanding performance and reliability. Choose our product for a unique combination of Norwegian craftsmanship, modern technology and lasting quality.

Refrences

Our product has achieved successful installations in several restaurants and these success stories confirm the product's reliability and effectiveness in the industry.

Lynx Kitchen Separator Exceeds Expectations With 99% Separation Ability

In our commitment to innovation, we have carried out extensive testing of the Lynx Kitchen. The results are convincing - the Lynx Kitchen separator shows outstanding efficiency in removing grease and particles from exhaust air, far exceeding today's market solutions. This is demonstrated by our impressive separation efficiency of over 99%.

Technical Data Lynx separator is based on a unique principle with a specially made porous filter that is self-cleaning and effectively separates liquid droplets from gas streams. This innovative system ensures exceptional purity in the exhaust air, and sets a new standard for kitchen ventilation technology.

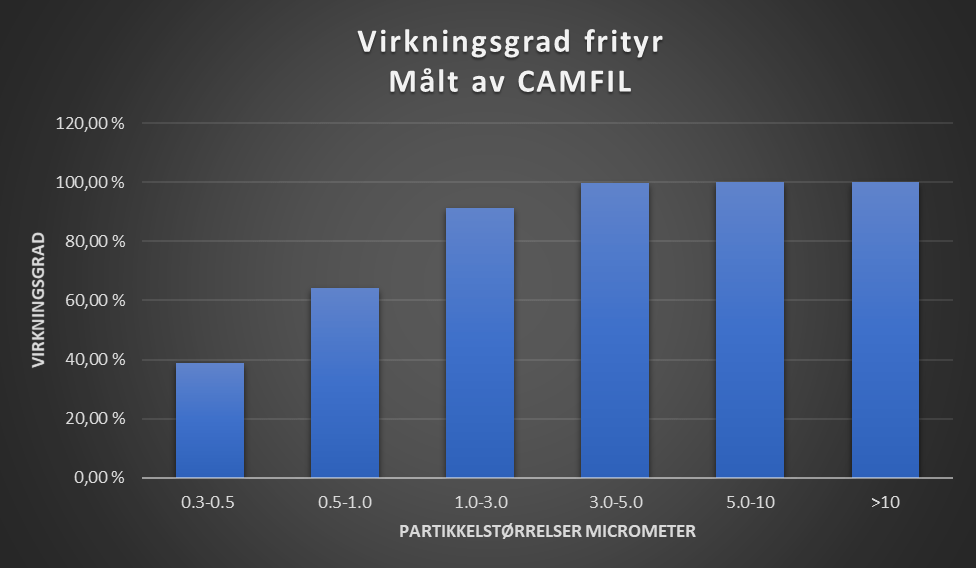

Lynx Kitchen has two-stage filtration. In the first step, all liquid particles from 0.1 to over 10 microns are removed, which gives the following degree:

Remaining particles are dry particles that are removed with dry filters that are changed once a year at a regular service interval, up to 3 times for those with the heaviest frying load

About us

From Concept to Reality

Lynx Kitchen has its origins in a successful preliminary project that was initiated in 2008, in collaboration with the research environment at NTNU in Trondheim. The aim was to transform the technology used in the oil and shipping industry into effective solutions for kitchen ventilation. Our journey from the early experiments to the development of a breakthrough solution clearly illustrates our dedication to innovation and quality. The thorough testing and refinement of the Lynx Kitchen represents not only a technological breakthrough, but also a commitment to deliver state-of-the-art kitchen ventilation technology that meets and exceeds expectations. We are proud to bring future standards to today's kitchens.

Fire sefety

Lynx Kitchen significantly reduces grease deposition in the system, strengthens fire safety and maintains reliable performance. Ideal for safe and efficient kitchen environments.

Energy saving

With our unique ability to remove impurities and liquids, we open up the possibility of placing highly efficient heat exchangers on the exhaust air from kitchen hoods, which was previously not possible.

Enviromental friendly

Our advanced technology ensures significantly better air quality with a reduced need for chemicals in the cleaning process, promotes a healthier and more sustainable kitchen environment.

Surveillance

Cloud-based monitoring 24/7, mounted inside a duct network, provides a seamless solution for continuous monitoring, optimization and proactive maintenance of our advanced kitchen ventilation system.